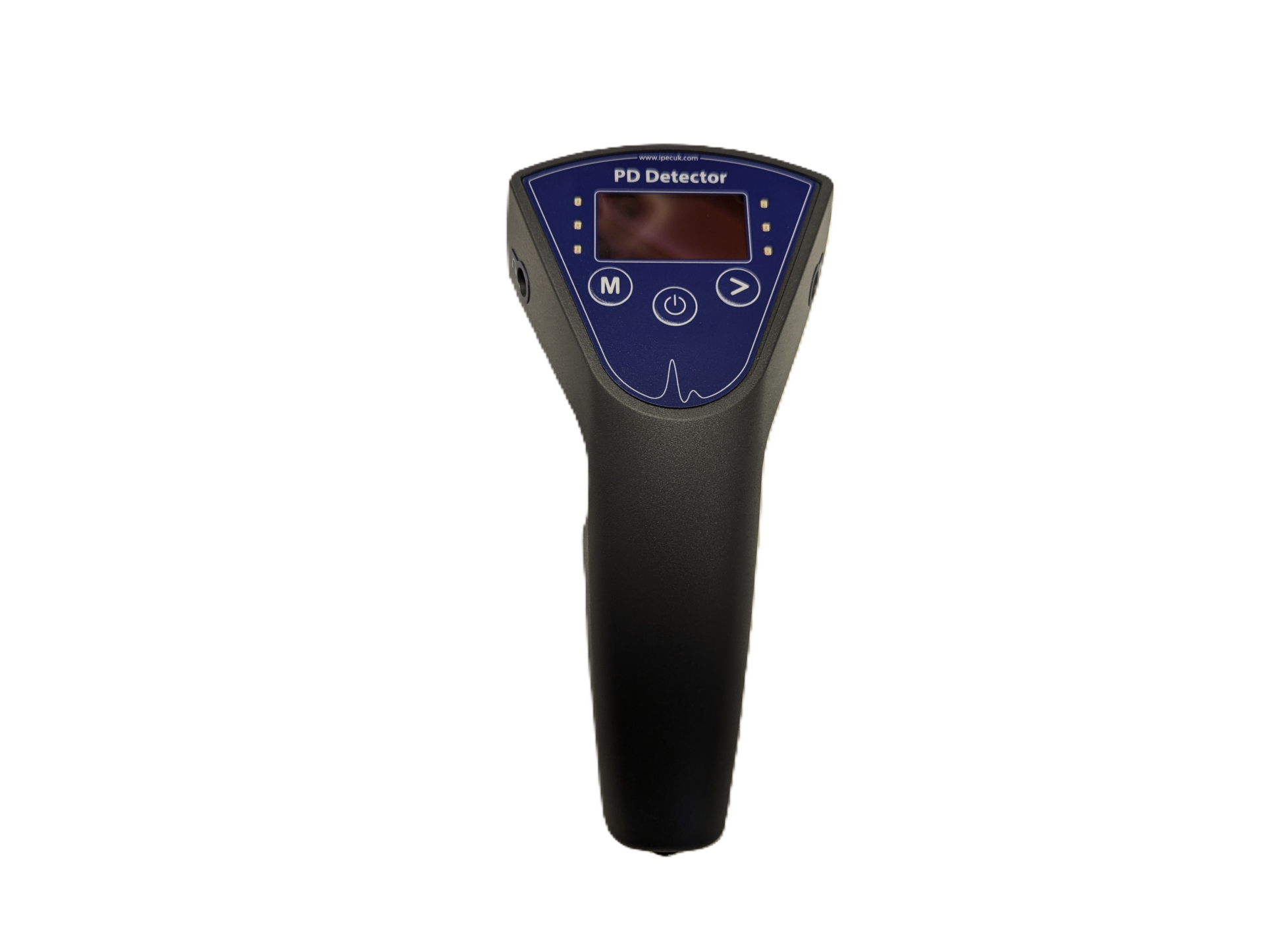

PD Detector

ASM Systems – Permanent PD Monitor

AA-Ultrasonic

IPEC offers various PD monitoring and detection solutions for Medium Voltage switchgear.

This can lead to:

MV switchgear is used extensively within the power network with varying levels of criticality to the overall system. Monitoring solutions can be tailored to individual customer needs to ensure a cost-effective solution with appropriate equipment.

MV switchgear are critical assets, and therefore, often suited to permanent monitoring. Using the ASM system, PD data is recorded and automatically processed 24 hours a day. Sophisticated algorithms consider PD trends and waveform analysis to comprehensively assess asset health. Alarms can be sent to asset managers when PD reaches a user defined level. Each ASM can support up to 128 channels and our full range of PD sensors.

In assets where failures may be less impactful, PD surveying may be the best solution. Using a handheld device, surveys are quick and simple to carry out and offer a snapshot of asset health. By consistently carrying out surveys and recording PD data the condition of switchgear can be effectively managed.

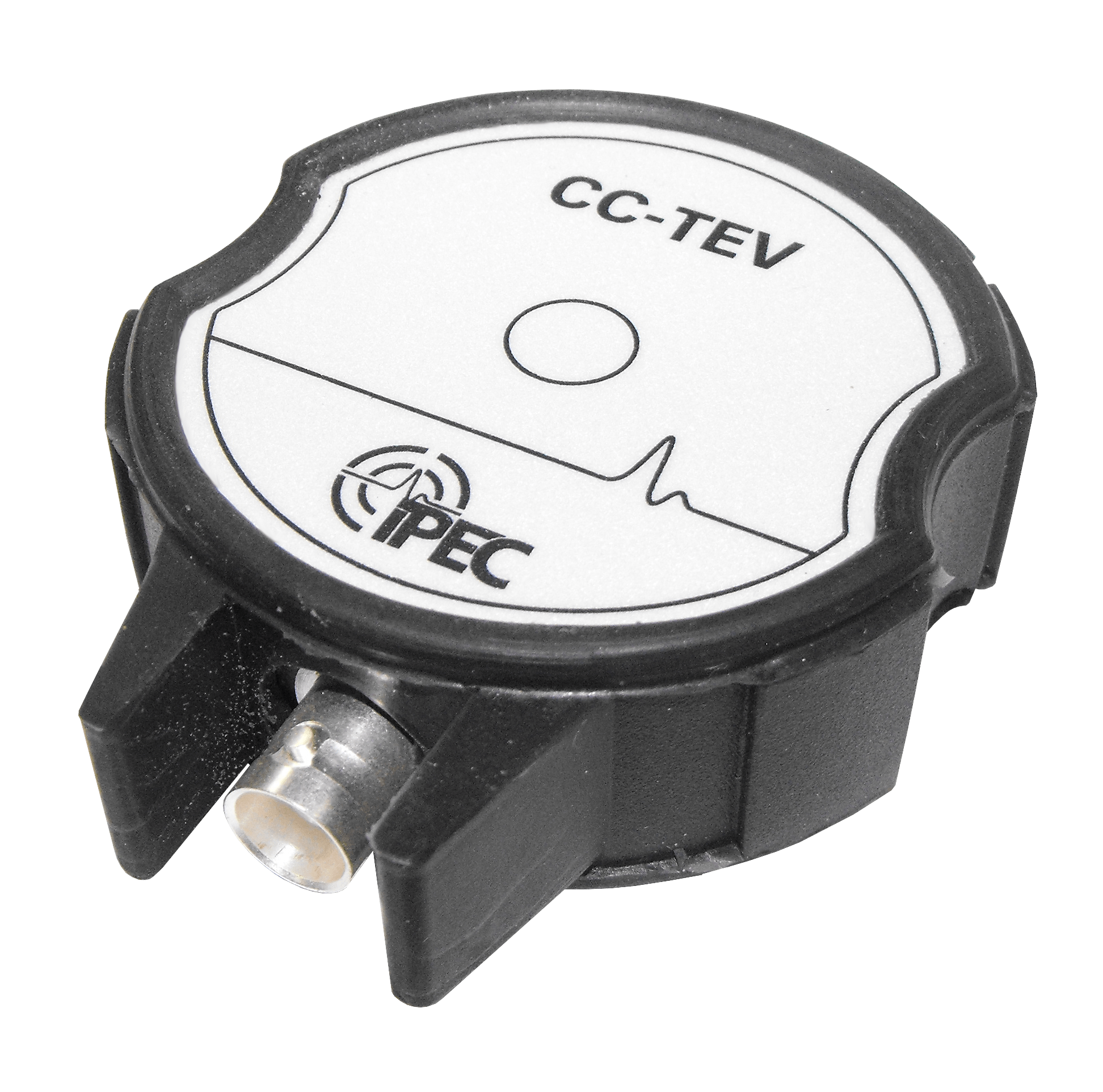

TEV sensors identify PD signals in the tens of MHz range and are extremely effective for use on air insulated MV switchgear. PD occurring in components within the switchgear will emit a high frequency signal which travels along the earthed panels to the exterior surface of the switchgear. A TEV sensor placed on the outer switchgear panel will detect the PD signal. TEV sensors can also detect background electrical noise, all of IPEC’s products use dedicated algorithms to effectively filter PD signals from noise for accurate PD detection.

Ultrasonic sensors can detect surface tracking activity in locations with exposed HV components. Highly sensitive microphones can be directed at potential defect points, often terminations or connection points, to pick up signals in the 40kHz range. Sensors can be installed within the switchgear, or by using a permanent or handheld sensor pointed between the panel air gaps.

Cables terminating in MV switchgear can also be monitored for PD. A High Frequency Current Transformer (HFCT) coupled to the cable earth or core will detect PD signals from up to 5km from the sensor location. Sensors can be used with either permanent monitoring systems or with handheld PD instruments. An HFCT sensor maybe also detect switchgear PD.

As GIS panels are sealed, there are fewer locations for PD signals to escape. TEV sensors will still detect PD signals, however, the placement of the sensors is more important. PD signals escape through gaskets or cable entry glands but may have travelled long distances and become attenuated. If PD is detected in MV GIS it is generally advised to investigate regardless of the PD level.