Testing and Monitoring of Power Transformers can help reduce catastrophic failures, which can have a large impact across the power network.

Transformers are one of the most critical parts of our power networks. On-line Partial Discharge (PD) testing of this type of HV asset can help identify defects in insulation before it can lead to asset failure. Both Distribution and Transmission level transformers can be tested or permanently monitored for signs of PD. High voltage failures of larger transformers can have serious safety implications for areas around substations.

PD Sensors for Power Transformers

Dry Type and Cast Resin Transformer PD Testing

A Dry-Type Transformer can be tested or monitored relatively easily, it is a similar application to Air Insulated Switchgear testing. PD occurring in components within the transformer will emit a high-frequency signal which travels along the earthed panels to the exterior surface of the equipment. A TEV sensor placed on the outer switchgear panel will detect the PD signal.

Ultrasonic sensors can detect surface tracking activity in locations with exposed HV components. Highly sensitive microphones can be directed at potential defect points, often terminations or connection points, to pick up signals in the 40kHz range. Sensors can be installed externally looking through vents and gaps in the housing.

Oil Filled & Transmission Transformers

Monitoring of oil transformers can be trickier than other substation assets, primarily due to the fact that traditional external PD sensors can not be used. PD signals can attenuate rapidly as they transit through oil, and the sealed nature of oil filled transformers will prevent surface current and voltage pulses from easily escaping.

Traditional HFCT and TEV Sensors can be used on cable terminations of the transformers. For PD detection in the main tank, however, these sensors cannot be used.

UHF sensors installed internally are the only effective sensors for PD Detection in oil filled transformers. Usually for existing transformers, these are installed via the drain valve, or a dedicated PD sensing valve specifically designed for this application. When PD occurs inside the main oil chamber, the UHF sensor will direct detect the Ultra-high-frequency radiated energy of the Partial Discharge. Some transformer manufacturers are beginning to install UHF windows to new transformers.

Contact Acoustic Sensors are sometimes used externally to test for PD. This is possible, though it must be noted that the signal may attenuate before it can be detected, so you cannot be sure the transformer is PD-free.

PD Monitoring and Testing Equipment for Power Transformers

Monitoring

Power transformers are suited to permanent monitoring. Using the IPEC ASM system, PD data is recorded and automatically processed 24 hours a day. Sophisticated algorithms consider PD trends and waveform analysis to comprehensively assess asset health. Alarms can be sent to asset managers when PD reaches a user defined level. Each ASM can support up to 128 channels and our full range of PD sensors.

Spot Testing

Portable equipment is better suited for dry type transformers, as it’s impractical to install UHF sensors for a spot test.

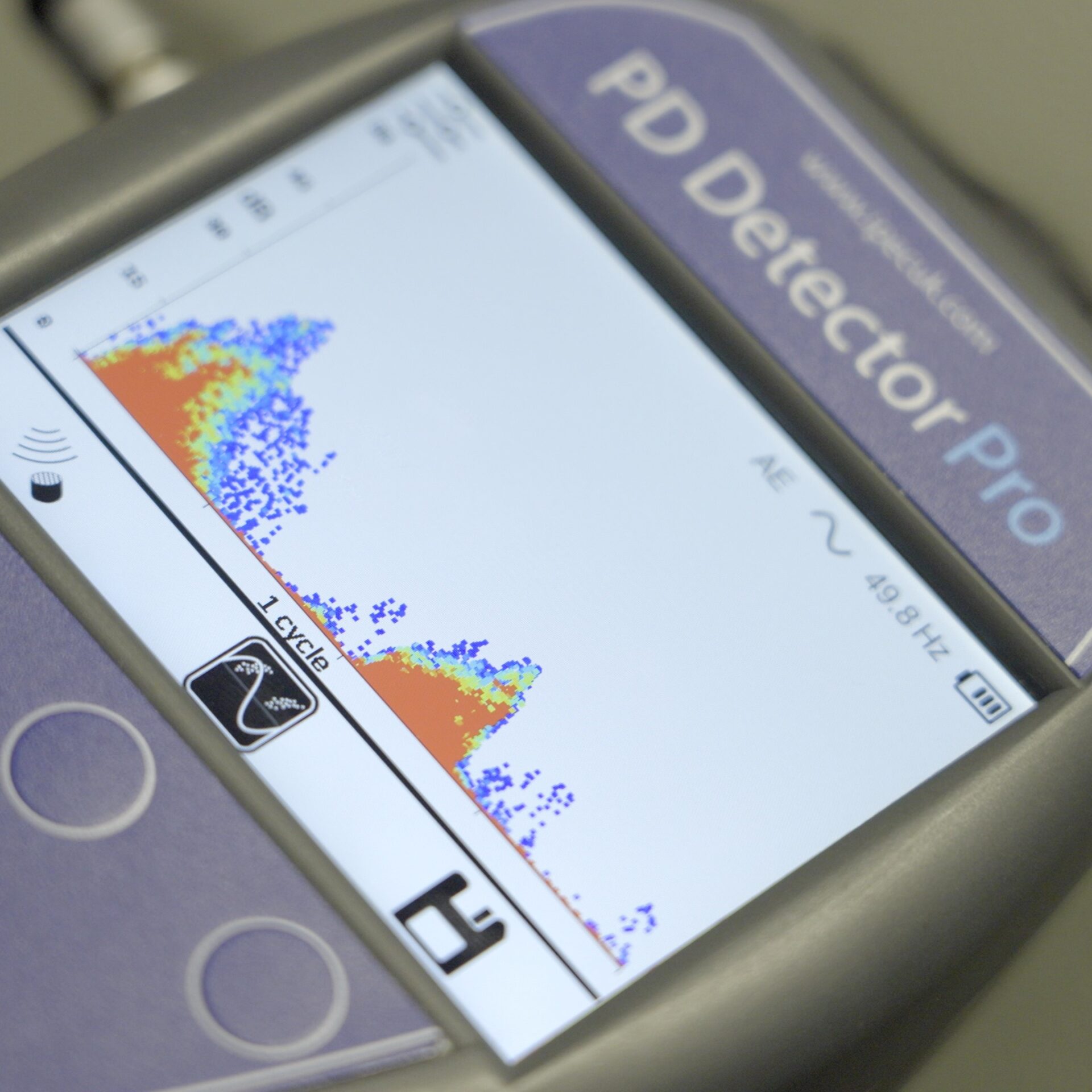

Using a handheld device, like the PD Detector, surveys are quick and simple to carry out and offer a snapshot of asset health. By consistently carrying out surveys and recording PD data the condition of the transformer can be effectively managed.

Services

IPEC’s team of expert engineers can conduct PD Surveys of transformer assets. The team can deploy a variety of tools for testing and location of PD. Producing a professional asset health report and condition assessment following the test.

Our turn-key service solutions are also available for transformers. IPEC’s team can conduct additional non-PD related testing for transformers, and support with regular maintenance and off-line testing.

Please contact use for more information.

ASM Systems – Permanent PD Monitor

The ASM is a permanent PD monitor for cables, switchgear and other high voltage assets. The ASM can be configured for any number of PD sensor channels. If excessive discharge is detected, the ASM raises an alarm that can be configured either locally or by email. This enables the long-term assessment of plant conditions to be carried out quickly and easily, from any remote computer. Suitable for all types of substation equipment, the ASM proves a powerful tool to an asset manager, providing continuous on-line condition data at the touch of a button.

Partial Discharge Spot Testers

Detect and measure PD activity levels with IPEC's range of Partial Discharge Spot Testers

On-line Partial Discharge Survey

IPEC provide Partial Discharge surveys using a number of products to accurately assess and detect the presence of Partial Discharge.