GIS Condition Based Maintenance (CBM)

Gas Insulated Switchgear (GIS) has a very high degree of reliability. Nevertheless, failures cannot totally be excluded, as per the experience of various customers globally. Failures are caused by irregularities during manufacture, assembling, and erection on site, but also the aging process during operation. These irregularities can be found early with Condition Based Maintenance (CBM) services and technologies. GIS PD Testing is one of the most effective CBM methods when it comes to GIS condition.

On-line Partial Discharge Services on GIS

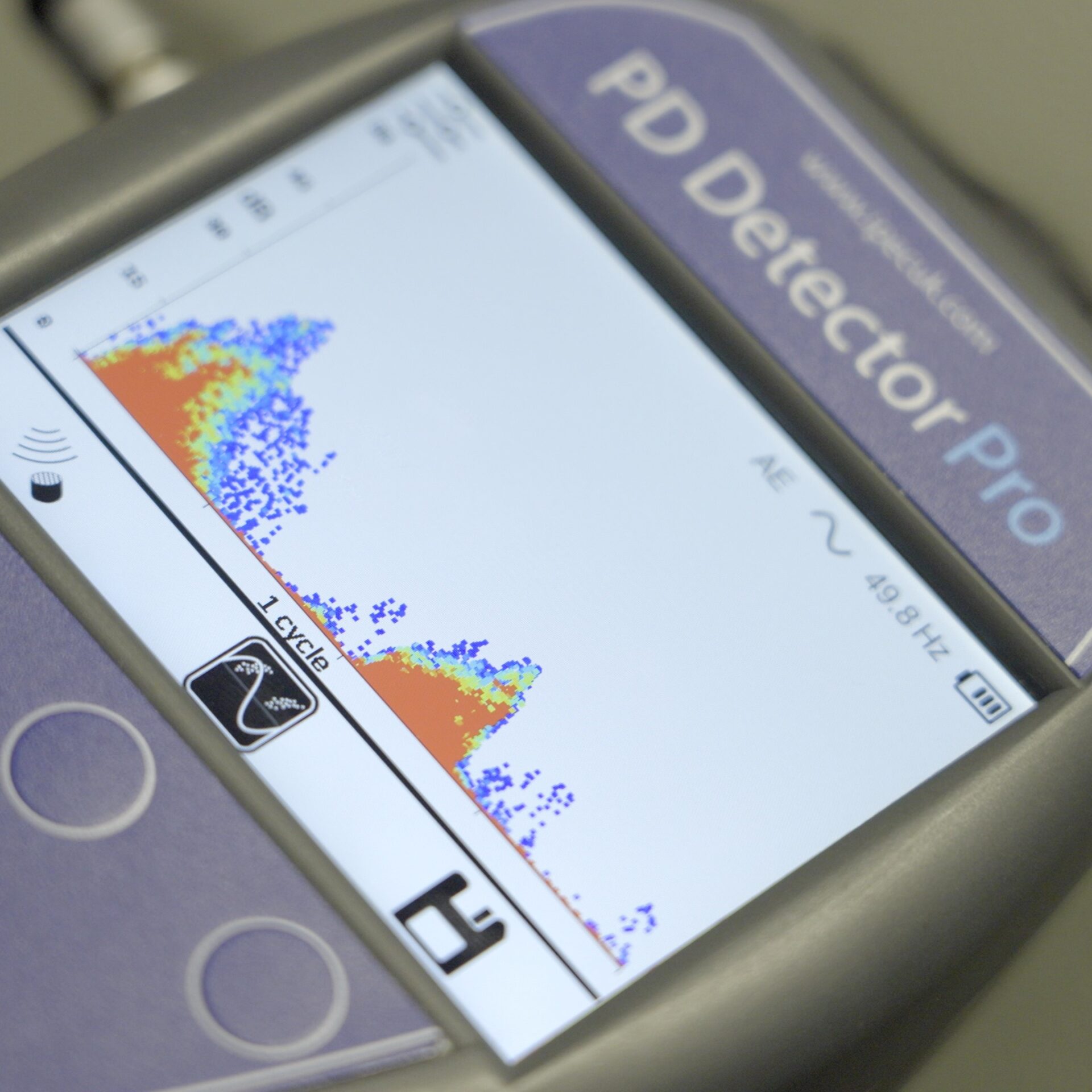

PD activity is the predominant cause of failure, occurring in over 80% of assets before an unexpected outage. IPEC’s GIS PD Testing Services can detect these defects, allowing asset managers to plan for repairs and maintenance, and improve the safety and reliability of the HV network. PD generates various types of emissions and different techniques are used to detect PD

- RF/UHF measurements techniques

- Ultrasonic sensors: Acoustic emission

- UV cameras: Light emission

- SF6 gas sample testing

Types of Defects detected with GIS PD Testing service

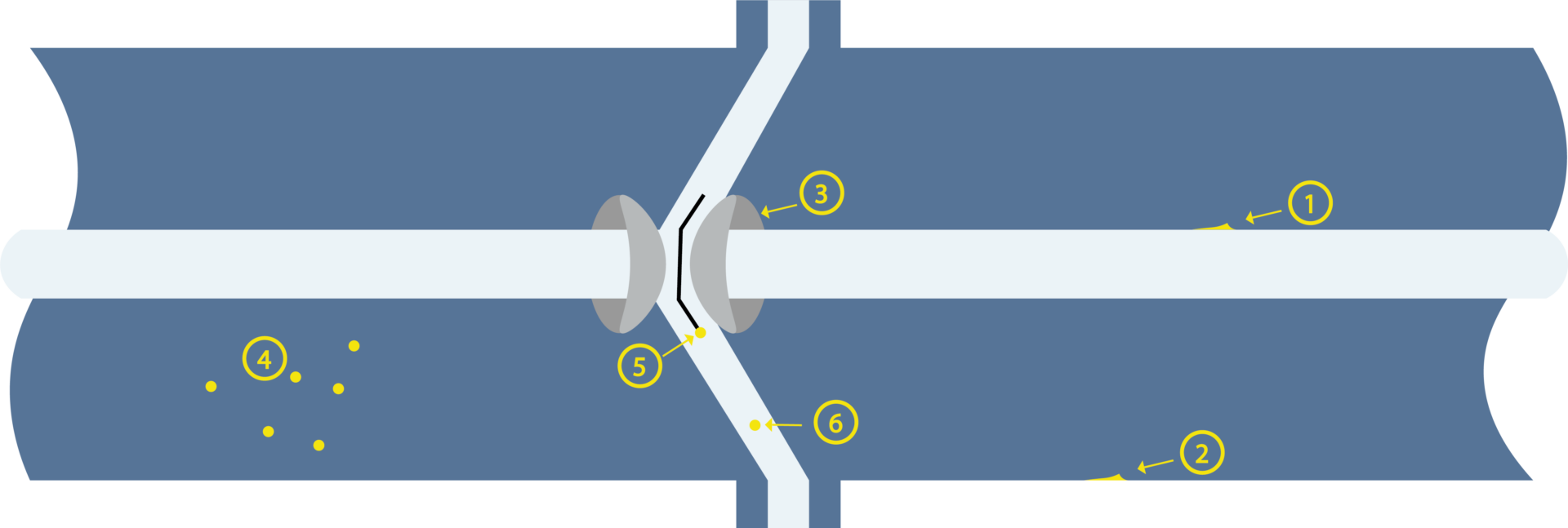

- Protrusion on conductor

- Protrusion on enclosure

- Floating parts / bad contacts

- Free particles on insulators

- Voids between screens and insulation

- Voids and treeing in insulation

What IPEC Offer

- Monitoring & Testing of GIS for PD – Continuous and Periodic

- Installation of PD Sensors – Temporary and Permanent

- PD Detection

- PD Location

- Sensitivity Test

- Reports with Recommendations

Where IPEC Teams are Based

- United Kingdom & Europe

- United Arab Emirates & Middle East

- Kingdom of Saudi Arabia

- India & South Asia

- Asia Pacific

- Other worldwide locations on request

Get in touch for more information

Contact us