AA-Ultrasonic

Noise Gating

IPEC offers Partial Discharge Solutions for large scale testing of cable networks.

Monitoring these cables means defects are found before faults occur to avoid outages in key locations. Excessive costs of replacing underground cable and the potentially high penalty for outages means cable monitoring is a cost-effective, proactive maintenance solution. Permanent monitoring solutions for On-line Partial Discharge (PD) Detection of cables are invaluable to large scale cable networks.

When a partial discharge occurs in an underground cable, usually in a joint or accessory, small high frequency currents are induced in the earth conductor and core of the system. These impulses travel along the cable away from the defect site. There will be an equal and opposite signal on the core and earth of the cable.

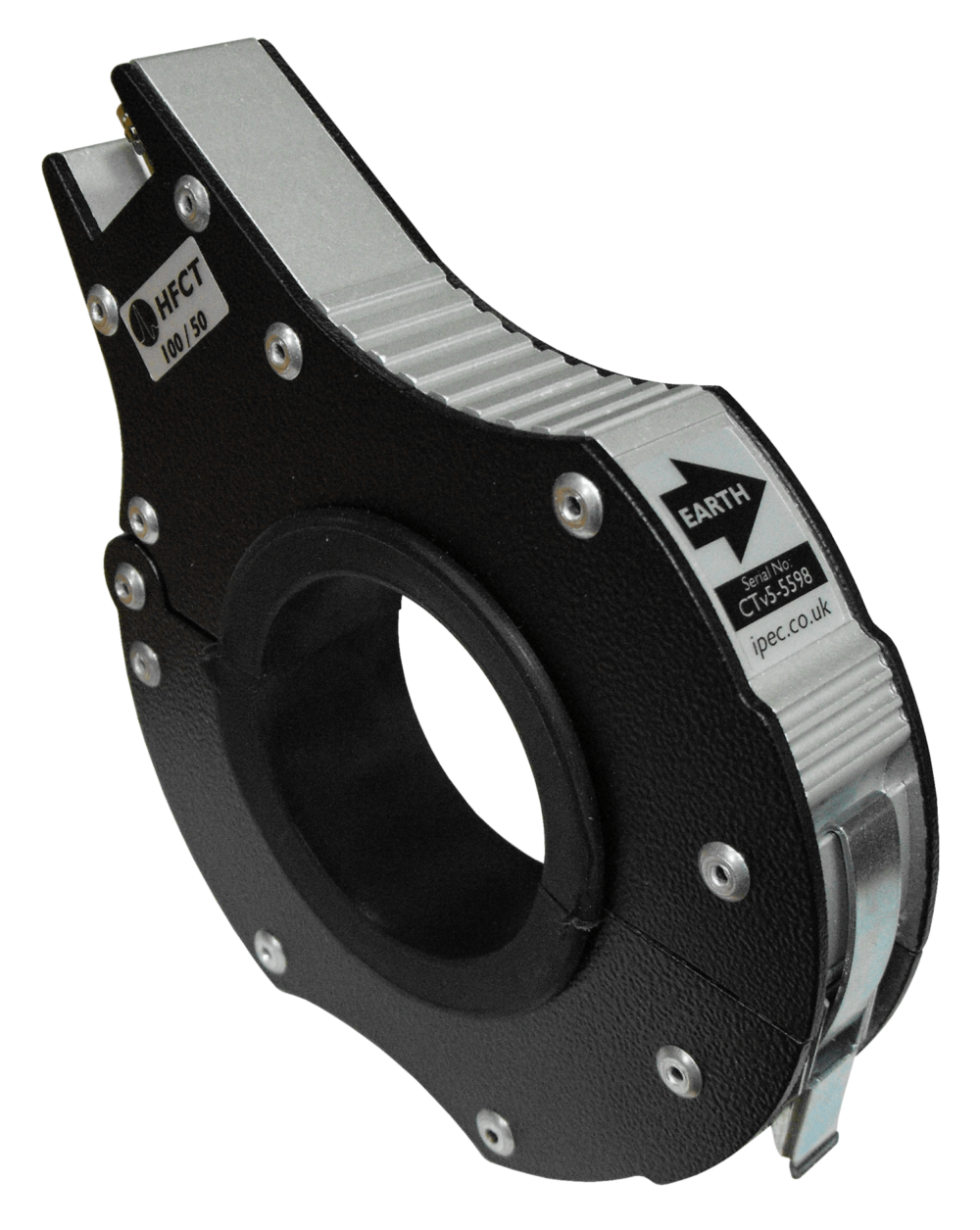

Cable PD is detected using an HFCT sensor placed around either the earth or core of a cable where the two separate, most commonly at terminations, or link boxes in higher voltage systems. A single HFCT sensor can monitor up to 5km of cable depending on condition and joints.

High electrical noise can be induced on underground cable systems. When detecting Cable PD the system for differentiating and analysing PD is critical. IPEC systems are designed for high noise applications and ensure PD is effectively detected, and false positives are kept to a minimum. Sophisticated systems such as IPEC’s permanent monitoring systems are capable of wave shape analysis due to an acquisition rate of 100Ms/s. This analysis of individual PD pulses is key to understanding the severity of PD in underground cables.

Handheld instruments and portable systems are also used to conduct spot checks on underground cables with HFCT sensors. These devices are able to filter noise effectively and give an indication if PD is present during the period of the test.

IPEC’s team of expert engineers can assist with PD testing of cables, along with other substation assets. Our tests include:

On-line PD testing offers the advantage of being able to test many assets in a short period of time, and without a shut down being required.

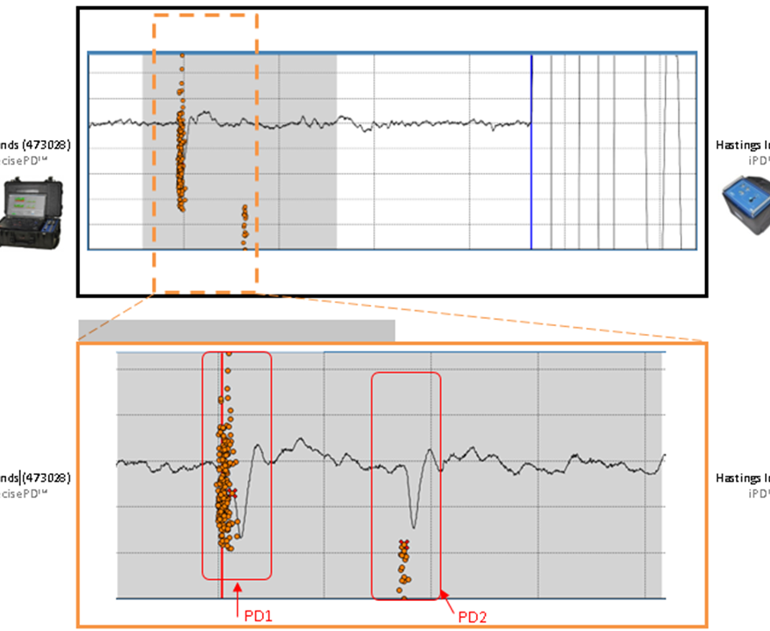

When PD is detected, locating the source is a key first step before deciding on the next action to take. In underground cables the PD source can be many kilometres from the sensor. On-line PD location is used to narrow the search to a single location, this will usually be a joint or other termination.

Off-line PD testing can also be used for PD location, a complementary more traditional technology used for this task.

IPEC’s ASM Monitoring system has the ability to locate PD On-line. A dedicated Cable PD testing tool like the Precise PD/Liona can also be used. In both cases, IPEC’s dedicated iPD transponder unit is used, to locate PD On-line, to an accuracy of around 1% of the cable length.

The results from the PD test will help verify the severity of the PD, and help planning teams begin the process of physical excavation for the repair.