Preventing Asset Failure: A Summary of Partial Discharge

31 / 01 / 19

Partial Discharge is attributed to the failure of 80% of electrical assets. Here we’ll explain what you need to know about partial discharge to help prevent asset failure.

![]()

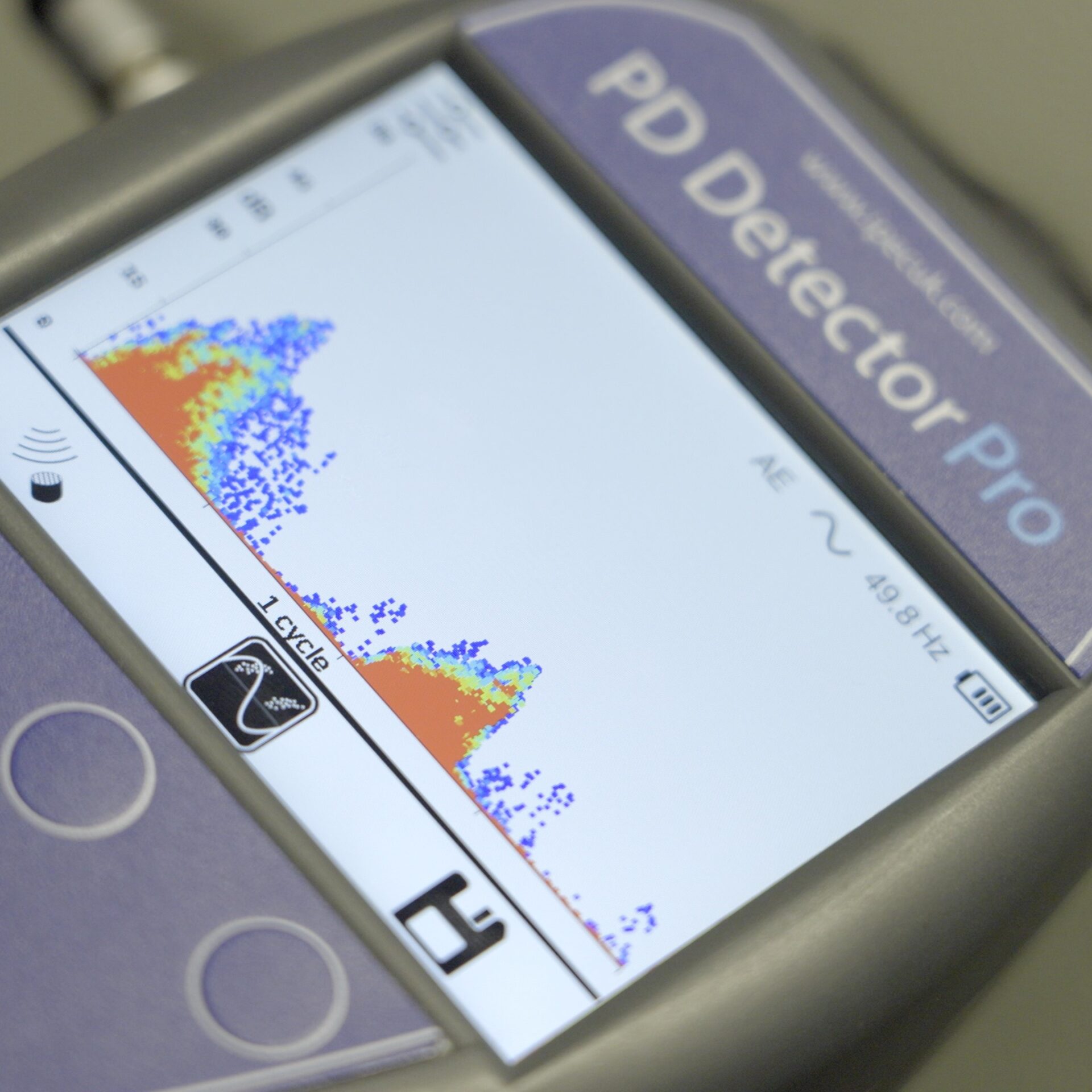

Partial Discharge is an electrical discharge that does not completely bridge the space between two conducting electrodes. It is the predominant cause of long term degradation and eventual failure of electrical insulation. As a result, its measurement is standard procedure in the factory testing of many types of high voltage equipment.

How does it occur?

Partial discharge occurs in gas filled cavities or defects in high voltage insulation. These defects can originate for many reasons; during manufacture, at installation, through natural deterioration with age, or through increased electrical stress or heating from current overloads.

What are the effects?

Undetected partial discharge is likely to lead to cable failure. This can result in loss of supply and unplanned outage. If partial discharge is present in switchgear, it can have serious effects. This includes safety implications, collateral damage and major disruption to operations resulting in financial loss.

What if partial discharge is detected?

The presence of partial discharge suggests there is a defect in the cable or switchgear that is damaging the insulation. To prevent asset failure, the partial discharge should be localised and repairs carried out immediately. Partial discharge activity should be monitored on an ongoing basis to warn against pending failure.

For a quick summary of partial discharge, click here to download our infographic.

![]()

To learn more about partial discharge theory and detection methods, click here. For more detailed information, enquire about our bespoke PD training courses.