On-line and Off-line Partial Discharge Testing: How Do They Compare?

12 / 02 / 19

Before we explain the difference between on-line and off-line partial discharge testing, let’s start with a little information about partial discharge, and what it is.

What is partial discharge?

Partial discharge is widely regarded as a predominant cause of long-term degradation and failure of high voltage (MV, HV and EHV) equipment. Partial discharge is often a small discharge occurring between electrode, but specifically at a location of a defect in the insulation. Over time these small discharges, caused by disproportionate electrical stress across the defect site, will continually damage the insulation until it leads to a catastrophic failure.

![]()

Luckily, there are methods to detect these partial discharge’s before failure occurs. This is where on-line and off-line testing comes in.

Depending on the defect type, and asset to be tested, there are multiple techniques deployed to test on-line and off-line. Read on as we explain the key characteristics of each.

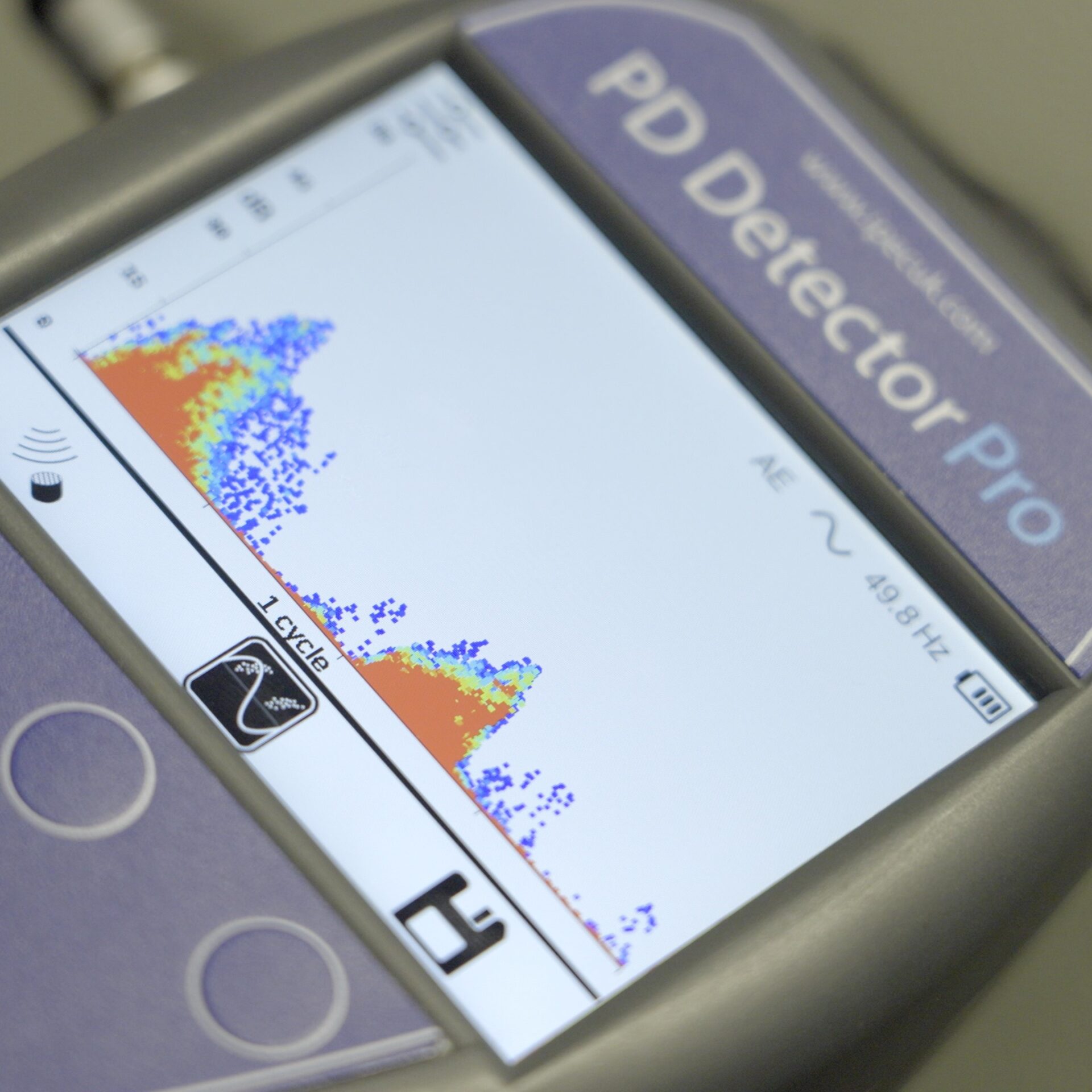

What is on-line partial discharge testing?

On-line testing is performed while the equipment is energised at normal operating voltages. The testing is conducted during real operating conditions, under typical temperature, voltage stresses, and vibration levels. It is a non-destructive test and does not use over voltages that could adversely affect the equipment. On-line Partial Discharge Testing is relatively inexpensive compared to off-line testing that requires interruption of service and production. For critical facilities that operate 24/7, this is an ideal solution for identifying insulation condition.

![]()

What is off-line partial discharge testing?

Off-line Partial Discharge Testing involves switching a circuit to disconnect it and then testing it while energised by a (usually very low frequency) test set. It allows the user to measure the cable system’s response to a specific stress level as voltages can be raised to multiples of U0. Off-line testing is useful for locating defects as noise levels are considerably lower off-line when compared to on-line. The challenge with off-line testing is that the equipment must be taken off-line and out of service. Off-line testing is also commonly used in acceptance testing on newly-installed cables.

![]()

Do I need to conduct both on-line and off-line partial discharge testing?

Both on-line and off-line methods form part of a successful asset management programme. By combining different technologies, you can ensure optimal equipment condition and reduced equipment failure and power outages.

On-line partial discharge can detect defects occurring during normal working voltages, and defects that may not be detected off-line. Off-line testing can detect partial discharge which may not be occurring normally, but that would form in the future. As such both methods can offer a unique perspective, and often the most established test regimes use both.

For a quick infographic summarising the key differences between on-line and off-line partial discharge testing, click here.

With 25 years of research and experience using on-line testing, IPEC are world leaders in partial discharge detection and location. IPEC develop market leading technology in the detection and location of partial discharge in cables, switchgear and accessories. IPEC have a long-standing technical collaboration with Baur, who are world leaders in off-line testing. Together the two companies have gained a great deal of experience from real life situations where both on-line and off-line partial discharge testing methods have been utilised.

For a full assessment of your partial discharge testing needs, contact us here.