Through On-line PD Monitoring or testing, asset operators can understand the condition of their HV assets across their Oil and Gas plant.

Oil and gas substations are important elements in the Petro-chemical and energy industry’s infrastructure, serving to transform, distribute, and manage the energy extracted. These elements collectively facilitate energy distribution, circuit control, backup power, and essential equipment operation. Transformers regulate voltage, switchgear manages circuits, and generators provide backup power during outages. Motors play a role in driving machinery. The configuration of substations is tailored to operational requirements, ensuring reliable energy supply and uninterrupted processes.

By understanding the condition of HV networks across the industry networks, asset operators can maximise up time and reduce costly failures.

Oil and gas substations vary in size and complexity. Various substations with different voltage levels, depending on the specific requirements of their facilities and operations. Substations could range from medium voltage (MV) levels, typically between 3.3 kV and 33 kV, to high voltage (HV) levels of 66 kV and above.

All MV and HV assets can be monitored and tested, in-service, for defects which could lead to failure.

On-line PD Solutions

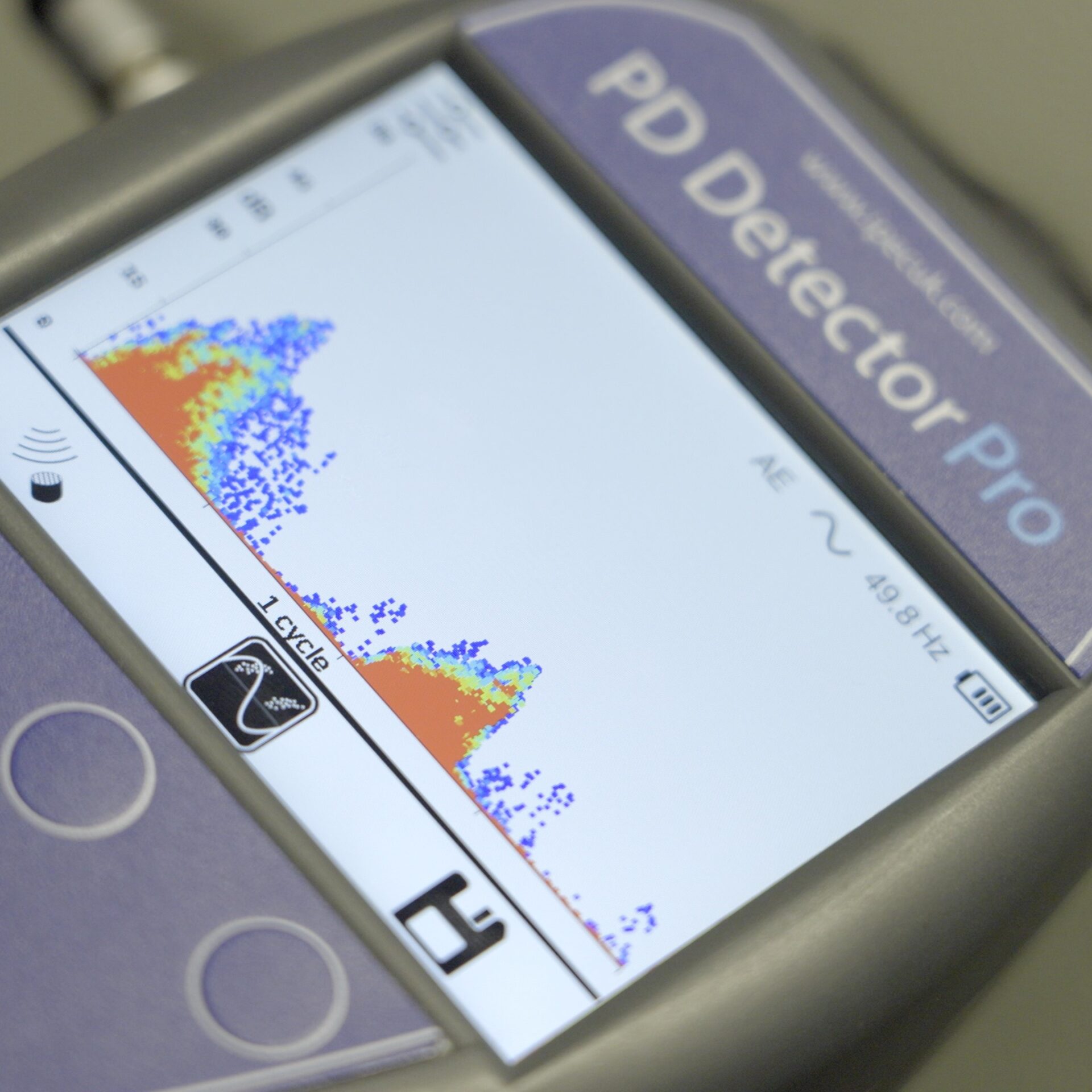

Routine on-line partial discharge (PD) testing is a standard practice for all assets within high-voltage (HV) networks. Specially optimized sensors are deployed for various components, including cables, switchgear, and transformers. These sensors—such as HFCT (High-Frequency Current Transformer), CC-TEV (Capacitive Coupling Transient Earth Voltage), and AA-Ultrasonic—are retrofitted onto existing equipment without requiring any outage for installation.

In critical oil and gas settings, motors and generators play pivotal roles. These components utilize HVCC (High-Voltage Coupling Capacitor) or HFCT sensors for PD testing. These sensors can be retrofitted or pre-installed before the assets are commissioned.

Portable PD testing instruments expedite the assessment of critical assets. If PD is detected, pinpointing the defect can often be achieved without a shutdown, allowing prompt action to manage the asset and prevent failure.

IPEC services extend globally, providing comprehensive testing for oil and gas facilities. Our team regularly trains asset operators and maintenance staff on proper PD management procedures on-site, along with effective utilization of PD test instruments for various asset testing.

On-line PD Monitoring of Critical Infrastructure

Sensors designed for partial discharge (PD) testing can seamlessly integrate with permanent monitoring systems. IPEC’s ASM system offers a customized solution for PD monitoring in substations, regardless of their size. The flexible system can be installed with up to 128 PD sensors, for comprehensive coverage of all your assets.

Compact PD Monitoring Systems, such as IPECs ASM Mini, can be deployed for dedicated monitoring of single rotating machines, compact PD monitoring systems can be deployed. These systems can be ATEX rated, ensuring compliance with safety standards.