Noise Gating

UHF

IPEC offers on-line PD testing and monitoring solutions for rotating machines.

Motors and Generators can be monitored and tested in-service for Partial Discharge (PD) activity which, if left unchecked, can lead to failure of the rotating machine.

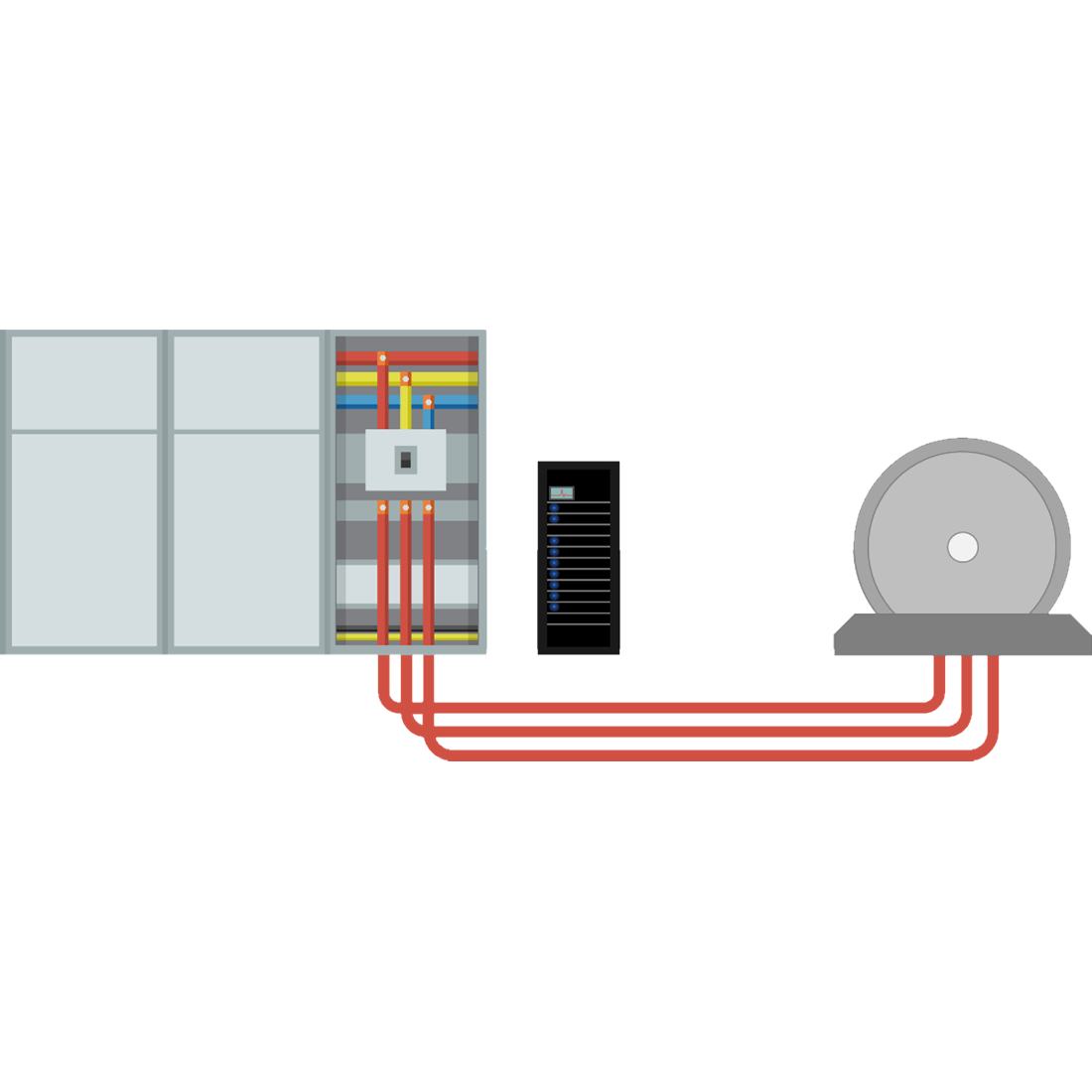

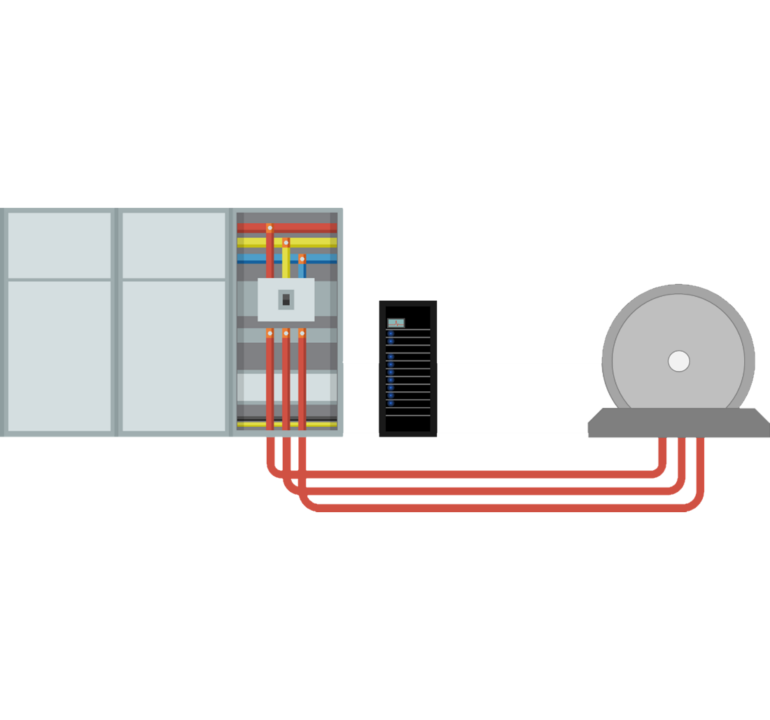

PD activity occurring due to a defect inside a rotating machine during operation induces high frequency signals which propagate away from the PD source. These pulses can be detected by PD sensors, and processed by an On-line PD Monitoring System or Portable PD Spot Testing system to trend and highlight system defects.

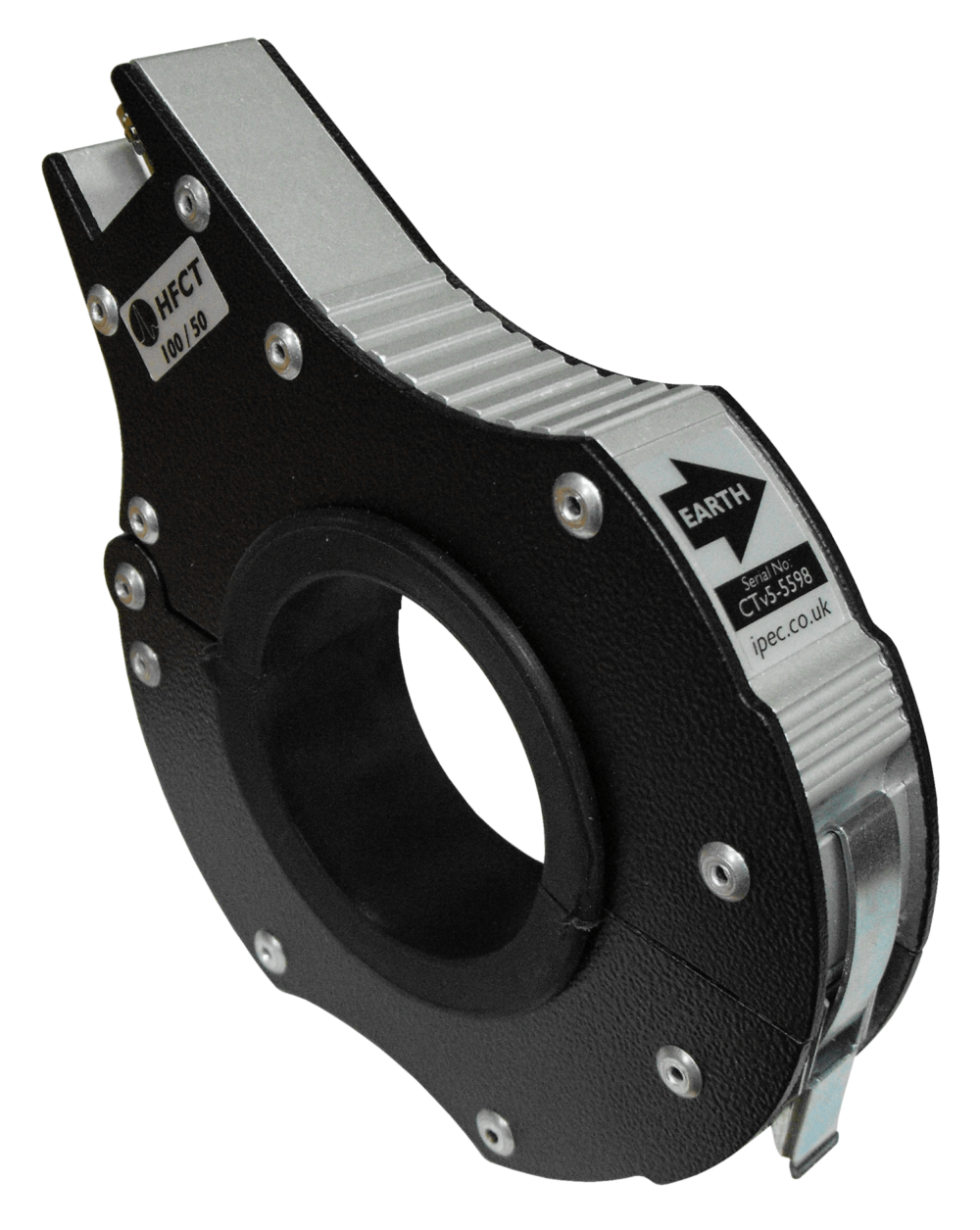

There are two primary sensor types often used with rotating machines, HFCT (High Frequency Current Transformers) Sensors and HVCC (High Voltage Coupling Capacitor) Sensors.

HFCT sensors are installed at the cable termination of the rotating machine. Just like regular HFCT sensor application on feeder terminations, the sensor is installed so as to detect PD signals induced on the HV core or earth. HFCT sensors can detect PD from many metres from the installation location, meaning the sensors can be installed at any earthing point along the cable, potentially outside of hazardous or inaccessible areas depending on the cable and earthing arrangements.

HVCC sensors are installed inside the HV rotating machines, directly connected to the HV terminals. The high frequency signal generated by PD activity, from either phase to phase or phase to earth PD, will be detected by the capacitive sensor, and the signal sent to the monitoring or test device outside the equipment. Once installed, the asset can be tested on-line, with no shutdown required.

Various solutions are available for on-line PD measurement, depending on the criticality of the Rotating Machine, accessibility, and resources available.

PD Testing Services are often conducted when routine tests are required across a high number of assets on a regular basis. IPEC’s team of expert Partial Discharge engineers have all the equipment and knowledge to conduct site surveys efficiently. Where resource is available, portable systems can be used by asset operators for quick testing of motors and generators of concern, or as part of a regular test program.

If 24/7 monitoring is required, in order to give asset operators continuous condition updates and maximise confidence in asset condition, IPEC’s ASM monitoring system can be deployed on site. The system is tailored to the requirements of each substation and can be used to monitor rotating machines, generators and associated cables and switchgear in a single coherent system.