HV Cable Monitoring

07 / 07 / 13

Summary

A permanent PD monitoring system has been installed by IPEC on a 5km long 110kV cable in Northern China. The monitoring system has HFCT PD sensors installed at cable terminations and cable joints. A fibre optic installed alongside the HV cable connects the sensors at each monitoring point, with the data acquisition and signal processing unit at one end of the cable.

The system provides permanent monitoring for partial discharge of the cable insulation, cable joints and the terminations.

The cable circuit is routed between an outdoor AIS substation at Xincheng, and an indoor GIS substation at Xihu in the centre of Ningxi, China.

Details

The 5km circuit has 9 cable sections with 8 joints, 6 of which are cross bonded. Monitoring points were installed in the cable tunnel, at the cable terminations and at joints No 4 and No 7, as indicated in the diagram below. This means that no joint in the circuit is more than 1 cable section away from a pointing point.

Each monitoring point has three HFCT PD sensors, one connected to the earth strap of each phase. The monitoring points are interconnected by a fibre optic running the complete length of the circuit.

The circuit runs through a tunnel that can be accessed from the street via man holes.

![]()

At each monitoring point, a Data Acquisition (DAQ) Unit was installed with 3 high frequency current transformer (HFCT) transducers. These are specially designed PD sensors that pick up very small HF current pulses induced in the cable earthing system in the event of a partial discharge.

Pulses from PD that occur in the cable insulation propagate along the cable length, and can be picked up by the sensors installed at the monitored joints with a high degree of sensitivity.

![]()

The DAQ Units pick up the signals from the sensors and continuously stream the data to the PD monitor installed at Xincheng Substation.

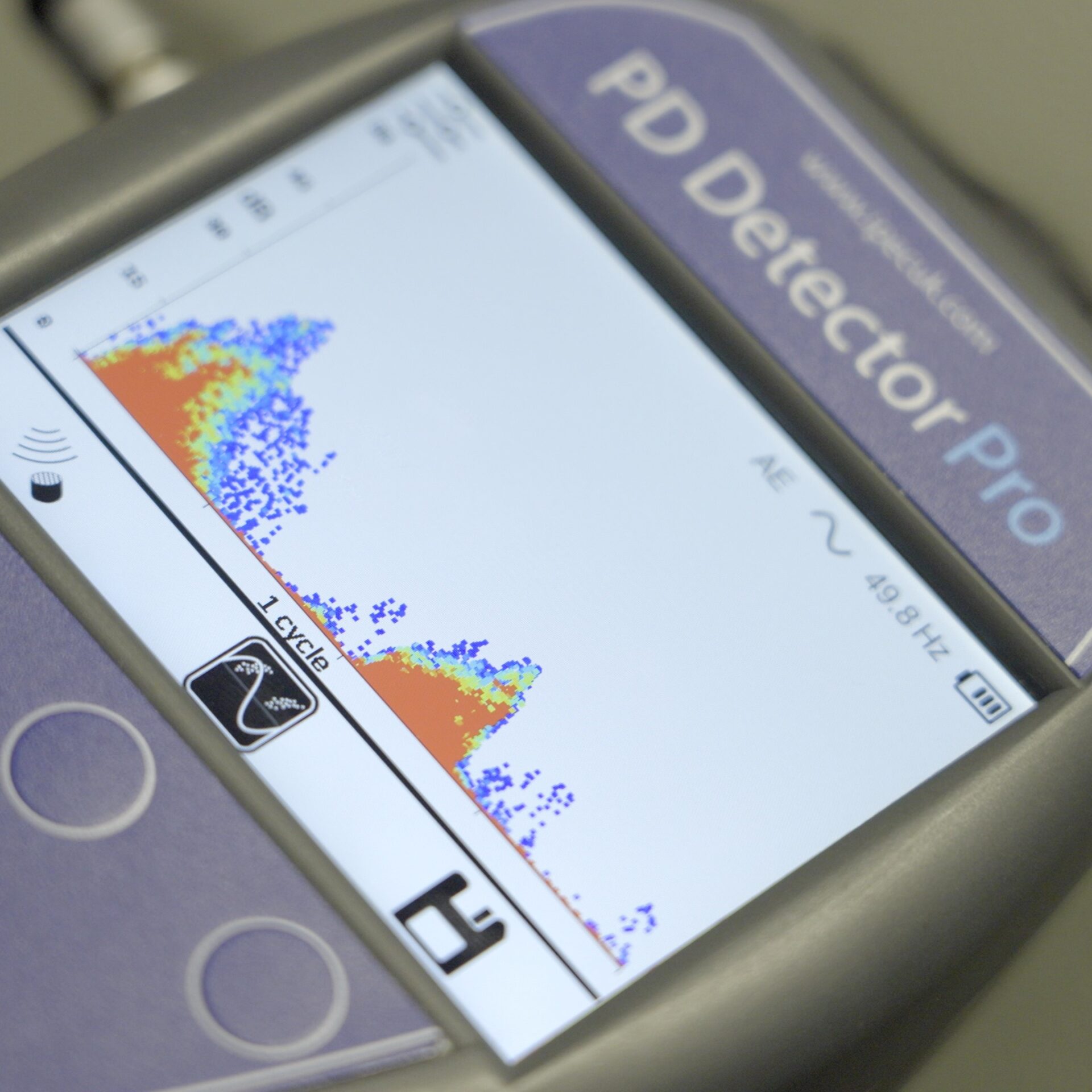

At the monitor the signals are sampled at a very high resolution. Sophisticated algorithms are used to automatically detect PD pulses that may be amongst noise signals many times greater in magnitude.

![]()

Environmental Compatibility

Some parts of the tunnel are prone to flooding and water levels could come higher than the mounting position of the DAQ Units on the tunnel wall. In addition, the DAQ Unit at Xincheng substation is mounted outdoors and exposed to rain. The DAQ Unit enclosures were therefore rated to IP67.

The DAQ Units are also designed to operate within specification at ambient temperatures between -20°C and +50°C.

![]()

The monitor installed at Xincheng Substation is rack mounted with managed UPS and a local data server. Data acquired by the monitor is stored locally on the server and made available via powerful web based analysis tools, allowing the user to observe trends in activity and get an overall view of the current and historical criticality of all monitored assets. In the event that any PD is detected, detailed analysis can be carried using the web tools that show Phase Resolved PD (PRPD) patterns and pulse wave shapes. This enables PD sources to be accurately located along the circuit length.

![]()

Conclusion

Although infrequent, failure in EHV cables has highly significant consequences for power transmission networks. In this case, Partial Discharge monitoring of inherently weak points in the network gives asset managers confidence in their system, as well as offering an effective tool to take pre-emptive action and remove potential failure points.