Switchgear – Air Insulated (AIS)

PD activity inside metal clad high voltage plant induces small voltage impulses called Transient Earth Voltages on the surface of the metal panels. TEVs travel around the surface to the outside of the switchgear, where they can be picked up externally using the PD-SGS.

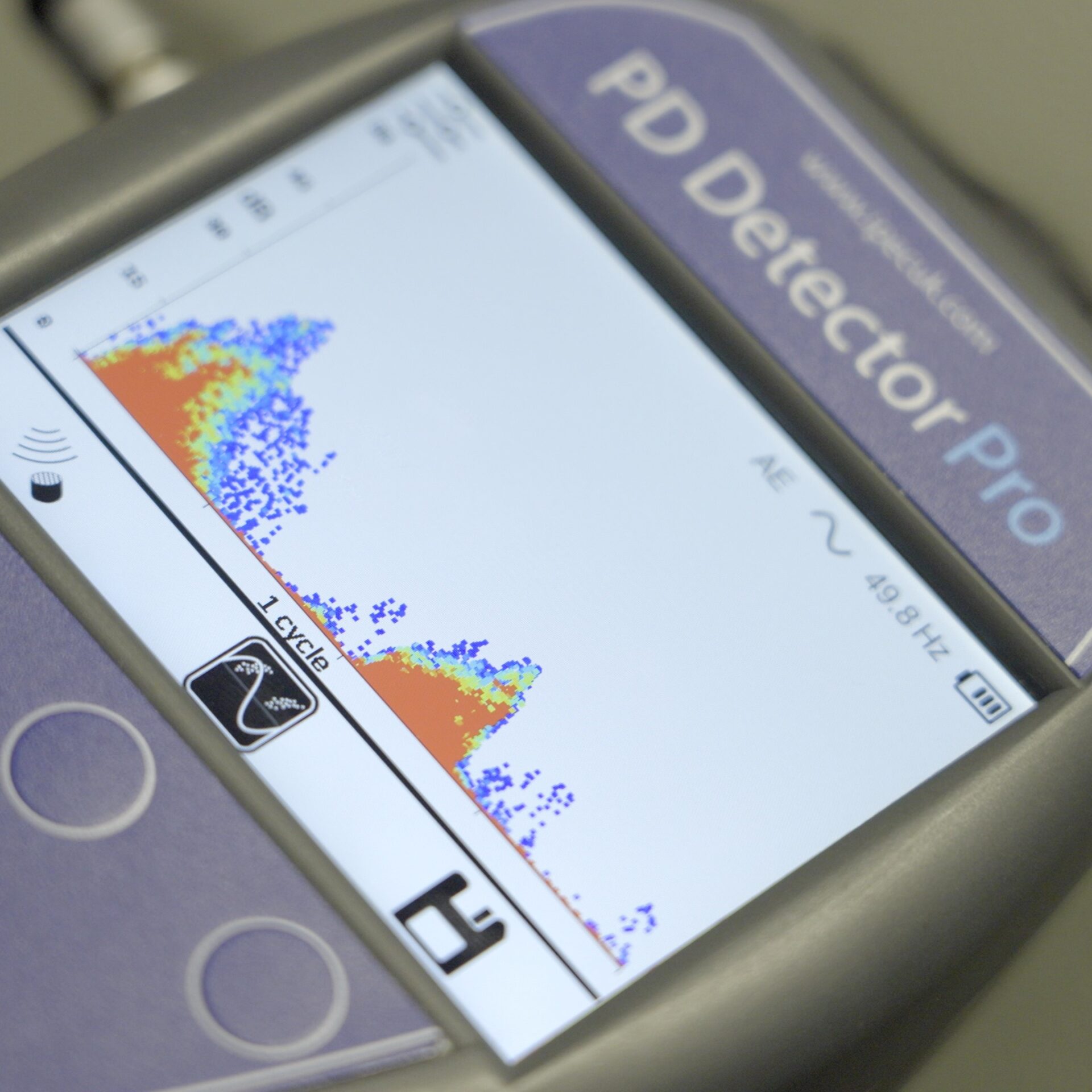

Defects on the surface of high voltage insulators are prone to a phenomenon known as surface tracking. Tracking causes carbon deposits that build up over time, ultimately leading to flashover and insulation failure. The PD Detector is highly sensitive to the ultrasonic emissions produced by tracking and enable the onset to be detected before insulation failure.

Switchgear – Gas Insulated (GIS)

Switchgear – Gas Insulated (GIS)

IPEC’s UHF (Ultra High Frequency) sensor is used to detect PD in EHV cable terminations, GIS (Gas Insulated Switchgear), GIL (Gas Insulated transmission Lines) & GIT (Gas Insulated Transformers). The sensors pick up signals in the UHF range (200MHz-2.0GHz) and are mounted against the insulating barrier spacers that separate components of the HV asset.

Cable

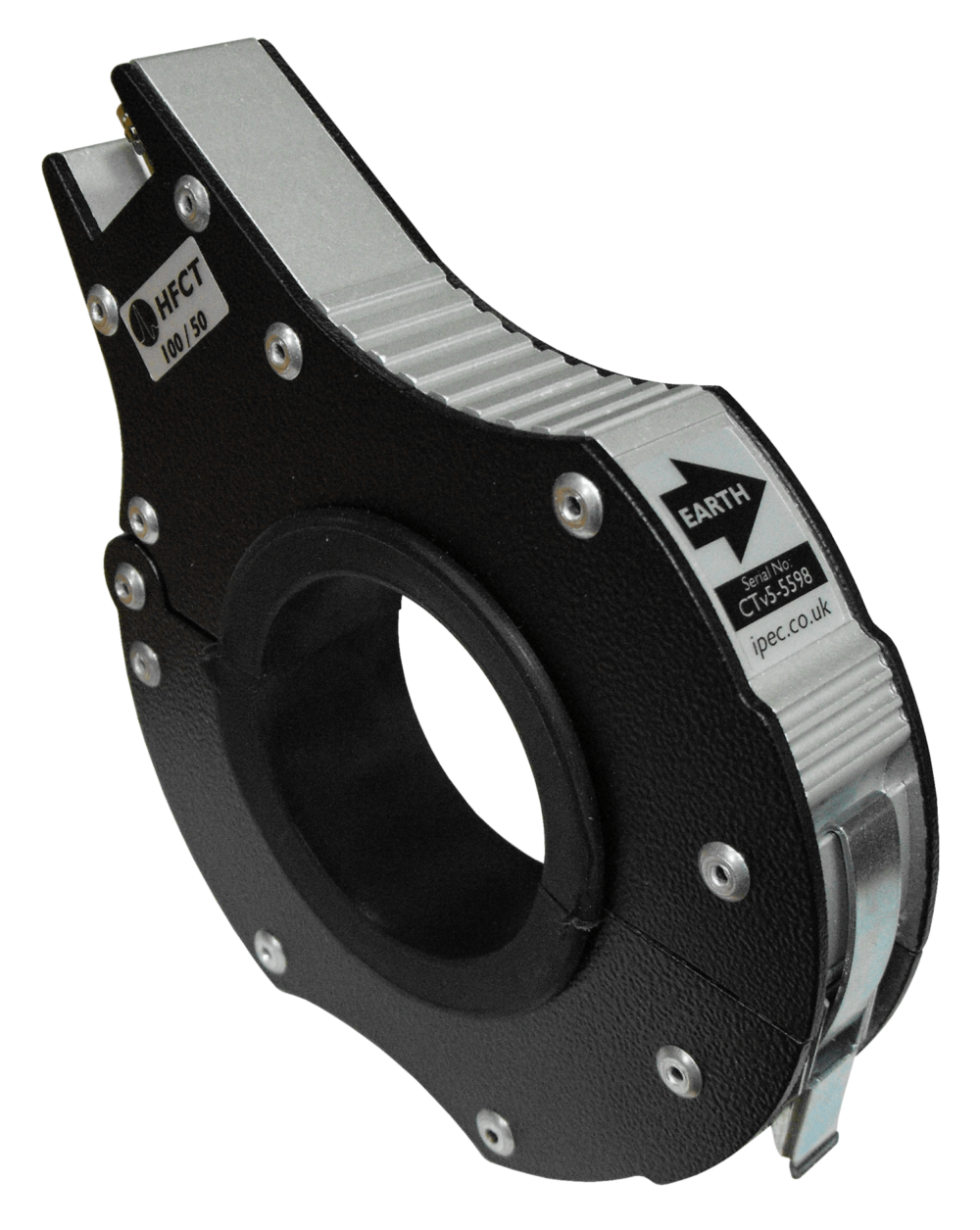

Partial discharge activity in solid high voltage insulation induces small high frequency currents in the earth conductor of the electrical system. These impulses travel along the equipment earth to the substation earth. Using a high frequency current transformer, they can be detected as they pass through the CT.

Advantages of the PD-SGS

Advantages of the PD-SGS

- Rapidly survey the whole substation – and detect MV and HV problems before they occur

- Personnel Safety Device – ensure the substation is clear of PD before conducting work

- Ensure accurate results – auto separation when the device detects background Noise instead of real PD

- Ergonomic and compact design – fits in the user’s pocket and is easy to use

- Long lasting battery – allowing a whole day of testing without requiring a recharge

Add-on Sensors Option

- HFCT: cable PD detection

- UHF: GIS PD detection

- Ultrasonic Parabolic Dish: bushing PD detection